I am just about to get pumping up my brew, and curious about pumps. What types of pumps do you brewers use? I do know, there are those whom prefer not to pump and continue ladling/gravity. I am going to build a peristaltic pump and have seen the feeds online, so I want to hear from you… Sneezles61 :blah:

I use a march 809 with an upgraded stainless head which I built into a toolbox. I use it to pump from my HLT to my MLT. I gravity feed from MLT to kettle, but then use the pump again to whirlpool, and then again to pump into my fermenter.

I have a 2 vessel system, HLT & MT/BK with a march 809 with the 815 impeller upgrade. I use it to pump sparge water from the HLT to sparge over my BIAB grain bag and then I pump through a plate chiller to my fermenters.

I picked up a steelhead pump from our host during a sale. Works fine for what I need. I use it to transfer from the HLT to the MT when doing 10-gallon batches, and to circulate through a CFC to sanitize during the boil and whirlpool/chill after.

I’m probably going to rig up a HERMS coil for the HLT and recirculate with the pump during the mash for temperature control via sparge water heating. May even go electric with the HLT.

The March pumps are fairly good pumps. The 809HS and 815 pumps seem to be most popular in the homebrewing circles along with Chugger pumps. The big concern with centrifugal pumps like these is losing the prime. That is less of a concern with a peristaltic.

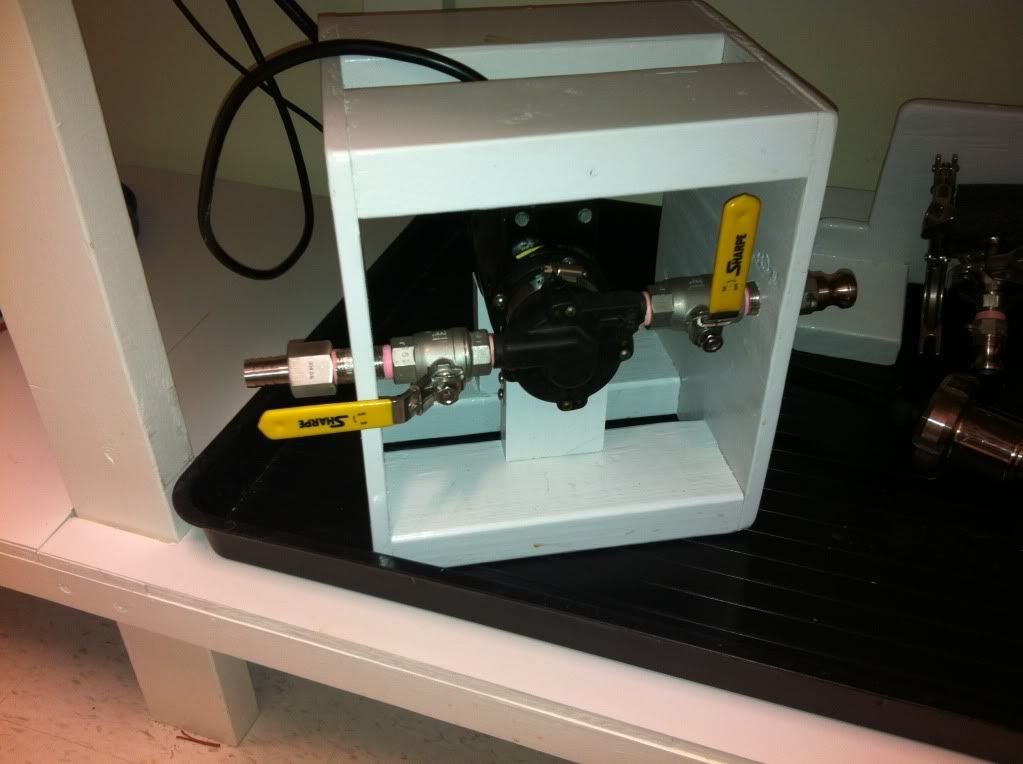

While a stainless steel pump housing may be nice, it is not necessary if the pump is properly protected. My 809HS that was upgraded with the 815 impeller is housed in a housing that prevents breaking the plastic housing. That pump is over ten years old and has never suffered a housing break.

I use a March 809HS with an 915 impeller upgrade.

[quote=“Denny”]I use a March 809HS with an 915 impeller upgrade.[/quote]Me too (815 impeller upgrade). I love it!

Yeah, it seems to make the pump pretty much self priming.

[quote=“porkchop”]I picked up a steelhead pump from our host during a sale. Works fine for what I need. I use it to transfer from the HLT to the MT when doing 10-gallon batches, and to circulate through a CFC to sanitize during the boil and whirlpool/chill after.

I’m probably going to rig up a HERMS coil for the HLT and recirculate with the pump during the mash for temperature control via sparge water heating. May even go electric with the HLT.[/quote]

I use an 809-PL-HS to recirculate wort through a heat exchanger (immersion chiller) during the mash and to circulate ice water during chilling. Keeping the pump below the level of the mash tun/ice water cooler makes it easy to prime. I move wort and sparge water by gravity and a two-quart pitcher. An electric brew kettle/HLT/heat exchanger water bath makes it easy to hold temps and heat the wort or infusion water for multi-step mashes. The electric kettle is easy and cheap to build. It’s also easy and cheap to add temp controls.

That’s kind of what I was thinking. I have an immersion cooker with temperature control that I can use to heat the sparge water in the HLT. Recirculating wort during the mash through a copper coil in the HLT via the pump seems like a pretty slick way of dialing in mash temp and doing step mashes. :cheers:

Upgraded my 809 with the 815 impeller upgrade on your advise. Thanks Denny! I no longer loses its prime. A good pump made better.

Question before I go looking it up. Is the impeller housing the same on both? I broke the hose barb off my spare pump. :evil:

Upgraded my 809 with the 815 impeller upgrade on your advise. Thanks Denny! I no longer loses its prime. A good pump made better.

Question before I go looking it up. Is the impeller housing the same on both? I broke the hose barb off my spare pump. :evil: [/quote]Yes, the impeller housing is common to both pumps.

Great stuff, so what I see and read is, the up grade is a bigger impeller and to be careful with the inlet/outlet. I see in Martins pict you have that addressed with the shroud picking up the strain. I will get a pump then while I build my peristaltic pump. I use a custom made 3 tier sculpture and gravity. When using keggles the height is of concern and I will change to more horizontal. I will also do a HERMS, mainly, for wort temp control on the lower mash temps. Thank you all, and if there is more input about the pumps please post! Sneezles61 :cheers:

Upgraded my 809 with the 815 impeller upgrade on your advise. Thanks Denny! I no longer loses its prime. A good pump made better.

Question before I go looking it up. Is the impeller housing the same on both? I broke the hose barb off my spare pump. :evil: [/quote]Yes, the impeller housing is common to both pumps.[/quote]

New housing and 815 impeller ordered. Thanks.

OK, the host had a special with the steel head pump, I now have a pump and will put into action this W/E. I won’t start at the herms side but will use for reticulating in the BK while chilling. Let the adventure begin! Thanks for the input… Sneezles61 :cheers:

I’ve done a a poor mans RIMS with mine a few times. I watch the inline thermometer while recirculating mash and light the burner to keep mash temp where I want it. Not the best setup but it works until i can get my electric brewery put together.

Good idea Danny, I found a 30 cup coffee maker at a garage sale, I will make that a heat exchanger fer HERMS. It got up to 175 degrees. Just having a pump opens up the possibilities. I have a 3 tier and use kegs so the HLT is way up there…… Sneezles61

Has anyone had any issues with their pump locking up during a brew session? I have a Chugger pump that I use for my direct-fired RIMS. Occasionally during the mash, the pump will start making a squealing sound and then lock up. The first time it happened, I took the head apart and found that the impeller was basically stuck on the shaft. I pulled it off, ran a brush through the hub of the impeller and put it back together. Worked fine. Apparently grit gets caught between the impeller hub and the shaft. This has happened a half dozen times to me, to the point where I can now disassemble the head, clean the impeller and re-assemble in less than five minutes. Looks like a NASCAR tire changer. Anyone else have this issue at all? Thanks in advance.

[quote=“MO-Brewer”]Has anyone had any issues with their pump locking up during a brew session? I have a Chugger pump that I use for my direct-fired RIMS. Occasionally during the mash, the pump will start making a squealing sound and then lock up. The first time it happened, I took the head apart and found that the impeller was basically stuck on the shaft. I pulled it off, ran a brush through the hub of the impeller and put it back together. Worked fine. Apparently grit gets caught between the impeller hub and the shaft. This has happened a half dozen times to me, to the point where I can now disassemble the head, clean the impeller and re-assemble in less than five minutes. Looks like a NASCAR tire changer. Anyone else have this issue at all? Thanks in advance.[/quote]Yes, it happens quite frequently. The magnet is uncoupling. I never take it apart. Just shut off and restart as long as you shut it off as soon as it starts squealing. There are certain conditions (full flow) where it will happen more often so I always throttle my discharge valve a bit to put back pressure on it and avoid the problem all together.

I don’t believe this is an issue of the magnet uncoupling. I’m using a Blichmann Tower of Power setup and I do throttle the discharge down. This is an issue of the impeller sticking on the shaft due to bits of grain or grit lodging between the impeller hub and shaft. I do cycle the power to the pump on and off and occasionally this will get the pump going again. Usually it’s just a matter of time before I have to do the NASCAR thing though. May just have to live with it.