I recently decided to rip apart my custom home brewery, and rebuild bigger and better. I had the old igloo coolers for mash tun and hot liquor tank, and a 15 gallon pot for the boil kettle, with a heater in the BK controlled with PWM and temperature feedback. I wrote the software and wired it all myself, but I would not have been able to brew a 10 gallon batch of my high abv stout in that system. So, I rebuilt! However, I could not locate a big insulated vessel to use as a MT, I decided to change to large SS pot. That would easily lose heat out the sides, so I had to make a HERMS to keep mash at the right temp. So then I needed to make my HLT able to heat up on its own too, so it also needed to change to a SS pot. I will post photos later, but here is what the new system can do and is comprised of

(2) 30 gallon pots for MT, HLT

(1) 15 gallon pot for BK

(2) heating elements, each with their own PWM heat controls

(11) motorized ball valves for routing

(1) stainless steel immersion chiller used as a HERMS

(2) chugger pumps to move liquid

(1) booster pump to increase liquid “lift” on herms circuit

(1) “home-made” glycol chiller to cool down my plate chiller

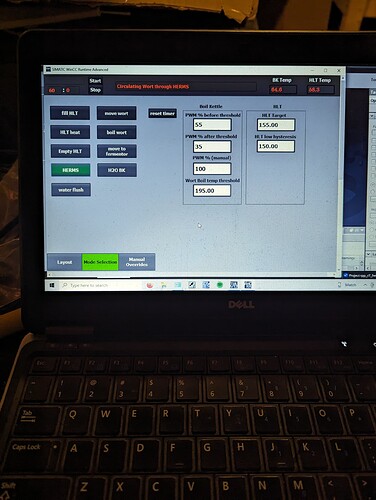

Custom software written by me to control the PLC:

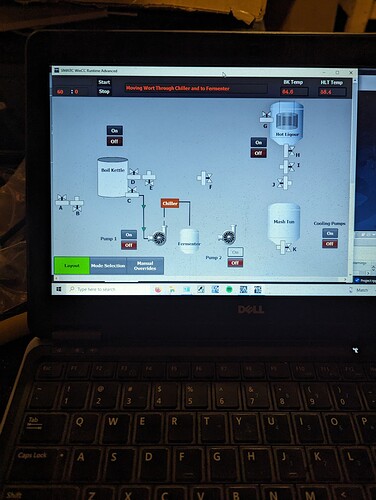

Choose which “step” of brewing I’m in (such as herms, boil wort, sparge heat, etc), all ball valves move to correct orientation. Touch screen will show the route that the liquid will take according to which program is selected.

Click appropriate button on touch screen to activate the proper pumps when needed (can’t use pumps unless the correct “step(s)” of brewing are active).

Click appropriate buttons to activate heaters. Can make temperature setpoints anything you want, including a hysteresis number. Can run each of heaters, independently, at anything from 15% to 100%.

Things it does:

Request water into BK

Request water into HLT

Heat BK for water or wort boil

Heat HLT for strike/sparge

Empty HLT into MT

Circulate wort through HERMS coil

Flush out any remaining wort from herms circuit

Move wort from MT to BK

Move wort from BK through plate chiller to fermenter