Can some one please tell me how to properly attach the spigot to the carboy. I bought the 1 Gallon Siphonless Fermenter starter kit and every time I try to attach the spigot it leaks. I have tried every configuration for the gaskets and I can never stop it from leaking. Sometimes it is fine for a couple hours with just water in it but it always starts leaking at some point. I am at my wits end and have accidentally cracked two carboys by tightening the spigot too much in an effort to stop the leaks. Can anyone please tell me how to stop the leaks or any tips on installing the spigot correctly? This is my first time brewing and I don’t want to lose or ruin my beer because I can’t attach the spigot correctly. I would like to avoid using tape or a sealant to stop the leaks but at this point I might have to.

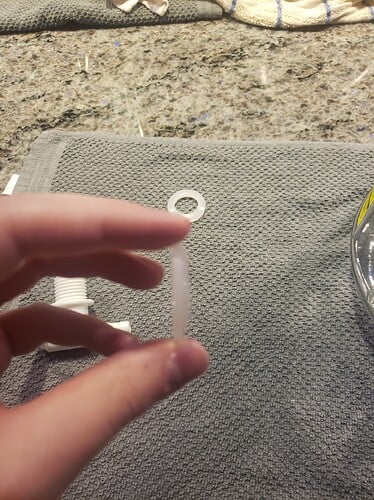

Do you have a picture you can post? There typically is a gasket on the outside and inside that go on both sides of the fermenter wall. Then a nut on the inside and the spigot on the outside. If you have Orings instead of flat rubber washers they are interesting in that overnighting will cause as much of a leak as under tightening.

Looks like the same spigot I bought for a plastic bucket. If so I think the seals are silicone and there is one for the outside and one for in. They really only need to be snug and a little more. Kind of like an oil filter. That said mine leaked on the first use. I just kept an eye on it and it quit but with 5 gallons losing a little was not as much of a problem as with a single gallon.

I can’t get pictures to upload correctly right now but the gaskets are more of a cone shape than a flat circle and I do have one on the inside and one on the outside. It can hold water for a couple hours but then water starts trickling out and I don’t know why.

My method is to put the spigot about a quarter turn out of alignment to pointing down. I finger tighten the inside as far as I can without really trying too hard and then use the leverage of the spigot to get that last bit into it.

try getting some new thinner gaskets from your local homebrew store.

Last resort could be food grade silicone sealant. Small tubes are available on Amazon. Might make it tough to remove to replace or clean the spigot.You really shouldn’t have to go through all of this to get it to seal.

I was thinking that the 1 gallon would have a tighter diameter and that maybe these gaskets are conical for a reason. @Maverick did you put the small end of the coned gasket toward the fermenter wall on the inside and the large side on the outside?

I put the larger side against the fermenter wall on both sides. That configuration had the best results since when I put the small side against the wall it leaks immediately.

Me dont use the spigot. Just a pump. Or the syphon. Me dont believe. In ataching to much to a fermentor. But a food grade silicone might be good.

I use one of those buckets for starsan storage. It’s never leaked a drop. It sounds to me like you’re trying to overtighen it and maybe deforming the gasket. It really just needs the rubber to seal against the bucket and shouldn’t need to be torqued on. Haven’t had mine apart in a while but I think @squeegeethree is correct, the small side is made to fit into the hole in the bucket.

I think he has a gallon glass container so if the hole isn’t just right the seal might not fit as well.

gotcha…scanned right over that part…

Thank you for all of your responses, I’ve been trying all your suggestions but so far nothing has worked yet. I might have to get a new carboy or new gaskets or just try to use tape or a sealant.

you should take some pics

I tried taking the best pictures I could but it is kind of hard to see the water leaking out of the bottom of the hole, and I can’t tell if it is coming out of the bottom or somewhere else and it travels to the bottom of the hole. This is also the best picture I could get to show the shape of the gaskets. From any other angle they look flat so it was the only way to show the slight curve.

I came here for the same reasons. I spent at least an hour+ trying all the different ways of installing the spigot to stop the leaks. I agree with other posters that it shouldn’t be so hard to get a seal with the silicone gaskets. The drilled hole is a little rough but not terrible. If the drilled hole has a chip in the edge, I wonder if that affects the gasket seal enough.

As of about 20 minutes ago, my Bubbler is full of tap water and not leaking…finally. For what it’s worth, this is what I did - The gasket arrangement was both gaskets tapering smaller towards each side of the the glass, which make sense. I lightly hand-tightened and then put water in the Bubbler. Then I started tightening and trying to center the gaskets in the hole. Sadly, it seems that it took more force than I thought it should’ve to stop the leak and I’m not exactly happy about it. I didn’t crack the glass as far as I can tell, but the nut is as tight as my fingers could go with water in the Bubbler. I’d like to think that having water in while I did this made some kind of difference but it’s probably just my imagination. Let’s see what happens tomorrow morning.

I thought about the sealant idea for a little bit but decided that I would get other gaskets first. These are thinner than some other setups I’ve installed on large glass water containers and might be worth a try. Thank goodness my other Bubbler is not this type.

Hope you get yours dialed in so you can get to brewing!

I wonder if O rings would be better. They usually don’t take much force to seal and are available at the hardware store.

Maybe there is a bad batch of gaskets out there. I have 5 spigotted fermenters and buckets and have never had an issue. My conical fermenter took a little fussing around with but those were metal parts and some teflon tape fixed that right up

I compared the fermenter gaskets to some other glass containers I have with spigots or taps. Didn’t help much when I noticed that each is a different thickness of glass. Since it’s not leaking as of this morning, I’m just going to leave it. Big plus, I didn’t break anything. Brewday next week will be the next test.

I never got it to seal so I wrapped it with teflon tape and it hasn’t leaked yet. I’ll probably buy new gaskets for my next batch.