Also, instead of using metal on metal use a piece of silicone tubing to connect them.

How is your pump mounted?

Now that mine is mounted horizontal I hardly ever use the bleed valve either.

Dannyboy58 - Right now my components are mounted with C-clamps holding them onto the rig frame. I am going to do a water test with the pump mounted with the output port facing up, and if I have priming issues I’ll try it horizontally (output port to the right) as you have done. Whichever works best will be my final configuration. I guess I’ve done enough texting and I should just try this out now. Thanks everyone for your feedback it is helpful, and fun sharing my build too.

Horizontal also

EDIT: the impeller is under the in/out put.

Creative. Looking forward to see the final product

I would if your main brew parts are stainless build. Use stainless. Dont go copper. Copper no big deal it works. But on the end your machine will look awesome

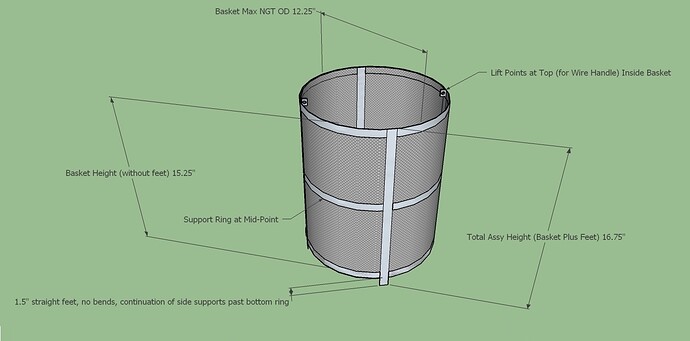

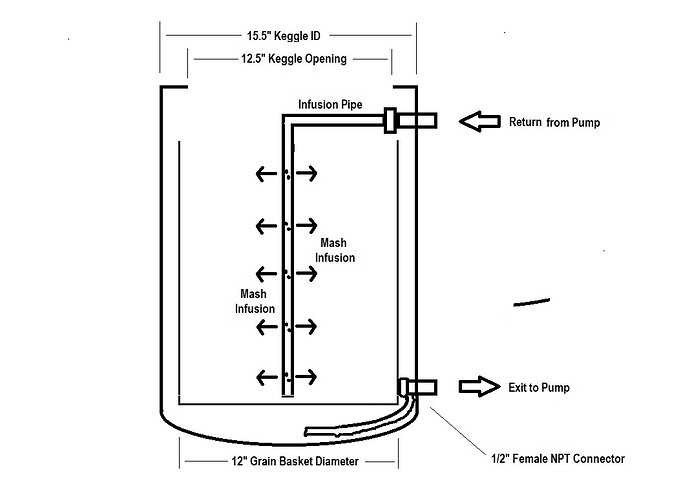

This is my tentative grain basket design. I plan to order this soon, along with a press plate and a hop filter. I am about to order it but I am thinking about SS mesh size. Has anyone built a recirculating system like I am? I’m thinking that I need a large mesh size (800 microns) else the mash will overflow the grain basket because the returning liquid cannot exit the basket as fast as it comes in from the recirculation pump?

Hey Sneezles61, remind me…you do recirculate exclusively right? If so what size is your basket in microns?

Recirc the whole time I’m mashing.

Grain basket is 400.

The hop basket is 600.

Sneezles61

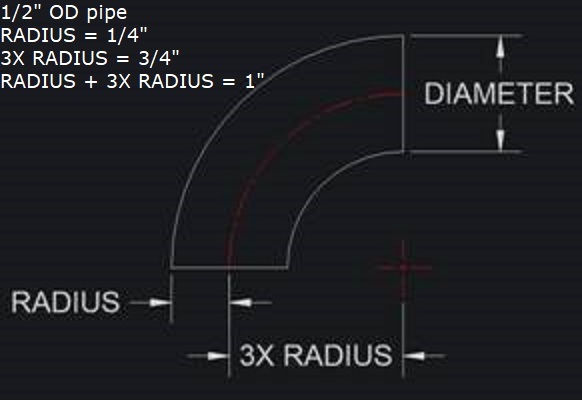

I will only use copper if I have to but so far I cannot find a SS elbow with a short-enough “turn distance”. The copper elbow I have makes a “quick” 90, but the SS ones I have seen are sweeps. Bottom line the SS ones will stick too far out into the interior of the keg, and therefore be an obstacle for my grain basket. At this point I am 90% sure I’ll silver-solder a copper elbow into the nipple and “snake” my way around to the bottom of the keg from there with more copper plumbing. The 1st attached image is typical SS tubing turn geometry I have found. The 1 inch distance is just too much. As you can see in the second image the copper elbow turns 90 degrees in a much shorter distance. Once the copper elbow is inserted into the nipple, the other leg is almost touching the keg wall.

Your recirc setup, I would have it so you can apply it from the top… Yours looks like it’s built in… That may be a PITA…

When I crush my malt… It gets dumped into my basket… Then I carry in to the brew room… Put it in my pH corrected water… Stir and be sure the dough balls are gone… Then, using a flexible silicone tubing… I dump it on top the wort… So my recirc is also directed through my whirlpool port… It’s not a fast recirc through the grain bed… I do stir every 15 minutes too… Why? Just a nervous twitch… And since my electric setup isn’t fully automated, I have to have something to do… Right ?

Sneezles61

Thanks Sneezles61 - my return for recirculation is an infusion pipe centered in the mash vertically, and has a quick-disconnect fitting at the keggle return connector so I can connect and disconnect easily. Should not be a PITA, at least I hope not.

My process would be to mill the grain into the basket, then hoist/lower it into the adjusted and heated mash water (currently I start with distilled water and modify it for the type of beer I am making). The tap water in Las Vegas does not taste good. The grain will be milled somewhere between coarse and medium, but not very fine…I need to zero in on this with some trial runs. I’ll check the pH and for dough balls and adjust/stir if necessary, then connect the infusion pipe and start the recirculation. I’ll put the lid on the keggle and monitor mash temperature, adding heat with the propane burner as required. I’ll check the pH during the mash and tweak that if necessary. When the mash is done I’ll remove the infusion pipe, and raise the basket and press it and allow it to drain into the keggle as I start the burner to heat up to a boil. When it has drained I’ll hoist and rotate the basket out of the way. Then I’ll put a hop basket in the wort and proceed with hop additions when the wort is boiling. If I see that my wort is very cloudy with trub (I expect it will be because the grain basket will have 800 micron mesh), I’ll recirculate as the wort heats up, without the infusion pipe in place, so that some of the trub is collected in the hop basket. The hop basket will have a finer mesh (probably 400 micron, I am still thinking that over) and should catch trub that the grain basket did not. I think I will order a relatively large volume hop basket, still thinking about that too. I have not ever done this method but that is my plan, and I’ll adjust it as I learn my setup’s strengths and weaknesses. I’ve tried to make this easier for brew day, and at the same time produce quality beer. We will see. I keep reminding myself it is the journey, not the destination, but I’m trying to make it both haha.

Cheers!

Is there a reason you’re planning an 800 micron basket for your mash? I would probably lean more to tighter mesh for the mash and looser for the hops. 400 should be fine for either or both.

Yes the reason I am going with 800 micron mesh on the grain basket is I want to ensure the basket drains as fast as the returning liquid enters the basket, else the basket will overflow. I want a high rate of recirculation, so the returning liquid will be coming in fast. I expect I’ll have to mill the grain a bit coarse, at least not very fine. This is my best guess based on everything I’ve read for the method I’m using. I’ve also read that most brewers consider 400 microns the sweet spot for pellet hops. No I am not 200% sure but this is my best guess on what I need. But I’m listening to you experienced guys.

I have another question guys. I have experienced low hop utilization when doing 3 vessel brewing, and I want to eliminate that problem going forward with my single vessel RIMS setup.

Instead of using a hop basket to contain the pellet hops during the boil, why not just put the pellets into the keggle without a hop basket (or any basket), and then at the end of the boil start up recirculation again to catch the hop trub with a 400 micron hop basket. This would give me maximum hop utilization, and trub removal before I route the wort to the plate chiller. Won’t the pump, valves, and plumbing pass the pellet hop material during recirculation without clogging? The real problem area with clogging is the plate chiller, but in this way I’m avoiding/minimizing this by filtering the trub out at the end of the boil. Not sure how long it would take to recirculate/filter out trub, but I could recirculate quite a while during the end of the boil if necessary.

My hop baskets will plug up, when using pellets… Not with cones…

Also, you’ll plug up your pump with free range pellets… Or at least mine has before I started putting them in a basket… Try a trub ring and getting a whirlpool to get stuff to collect in the ring… It used to work…

I’ve tried to get crystal clear worts… Finally just gave up… I brew so I can put 6 gallons in my fermenter… From trub and yeast, there will be stuff I leave behind but I still get a full keg…which incidentally holds over 5 gallons…

Sneezles61

Gotcha. Makes sense. When I’ve tried to recirculate with my brew bag I have to limit flow to a very low rate. Now I can’t say for sure if that’s because of the bag or just the grain bed itself.

Either way if you’re getting good recirculation you’ll filter a lot of the particulate matter in the grain bed itself.

I would NOT go free range hops in any recirculating system. You’ll have a mess on your hands, or more specifically, in your pump and ball valves.

I hear people talk about how bagging or using a hop filter in the boil affects their hop utilization but honestly I’m not sure how you measure that. Can’t say I’ve ever noticed and I’ve bagged my kettle hops for years.

Anything that limits flow can easily result in an overflow, whether it be a grain bed, grain bag, or basket. We have to dial our pumps way down during vorlauf to prevent overflow and dry pump during recirculation. Just part of the game and figuring out YOUR system.

In regards to hop utilization, pumps, and clogging. At home I’ve used a 400 micron SS hop basket. I felt I didn’t get a true boil in the basket by my visual observation, as well as flavor observation. I bumped my hops up by 10% and felt I got the bittering that I wanted. With bags I get what I want. Commercially we free range but we are also talking about 1.5” tubing with very powerful pumps and a BK that’s designed to capture trub and hops in the center while drawing off wort in different areas of the kettle.

I free range as well and my false bottom catches 95% of hop and trub. Looks like you have the room still for a false bottom @MikeBeer

Loopie_beer - just to be clear, when using the 400 micron hop basket were you able to get both hops bittering, and flavor, that you wanted with 10% increase in pellet hops? What was the size of that basket?

In other words were there any drawbacks in using the basket if you bump up the hops amount?

Also, is there something special about “boiling” as long as the temperature is at the boiling point? I’m thinking it is the turbulence that matters in hop utilization, and not the actual bubbles, as long as it is at boiling temperature? Right?