I brewed my first batch of beer on September 17, 2013, took lots of notes and pictures, and have a lot of questions. I appreciate any feedback and help. (Not sure why my images aren’t showing up, but I’ve left them inline here anyway.)

I followed the instructions for making a Pale Ale in the book, “Beer Craft”, by William Bostwich and Jessi Rymill.

Here’s the recipe:

Grains:

2.25 lb Maris Otter

0.25 lb 20L Crystal malt

Bring 5 qt strike water to 163F

Mash for 60 minutes at 153F

Sparge:

Target pre-boil gravity: 1.035

Boil & Add Hops

20g Cascade @ 60 minutes

10g Cascade @ 20 minutes

10g Cascade @ 1 minute

Chill:

Target original gravity: 1.055

Ferment:

Yeast: California Ale (WLP001), 1/2 tube

68F for 2 weeks

Target final gravity: 1.012

Bottle:

Bottling sugar: 22g

Here’s what I did, with pictures and video:

Night Before Brew Day:

I filled the large (12Q) Le Creuset stockpot with tap water. Let it sit out, uncovered, overnight (about 15 hours).

My water report says that we have 0.4 ppm Chlorine in our supply.

[color=#BF0000]Question 1: Is 15 hours long enough to get rid of any chlorine?

Question 2: I left it uncovered. Would it be better to cover, and if so, how much of a gap should I leave to allow for gas to escape?

Question 3: Is this a low level for chlorine? Do I even need to do this step?[/color]

Brew Day:

7:30am – took yeast and hops out of fridge, and put on counter to warm up to room temperature. [Yeast says to take out of fridge 3-6 hours before using.]

Started assembling equipment.

Took measurements on 12Q Stockpot (measured from top metal rim):

23cm = 0 gallons (empty)

16cm = 1 gallon (4 quarts)

12.5cm = 5 quarts

8.5cm = 2 gallons (8 quarts)

Used 12Q Le Creuset stock pot as mash tun and boiling kettle

Used 16Q aluminum stock pot for sparge water / lauter tun.

Filled big Le Creuset with 5 quarts of the water I left out overnight. (as directed in the recipe).

Calibrated refractometer since this is the first time I’m using it. (yes, I have a refractometer rather than a hydrometer) Added a few drops of distilled water, and calibrated to SG of 1.000

Put equipment in bin, filled with 2 teaspoons of Star San + 2 gallons of water. Let sit for 1 minute. Since I put the stockpot lid and big funnel in too, and they only fit half way, rotated it and let sit for another minute. I didn’t take these out until I needed them later, didn’t rinse, and didn’t dry them.

10:05am: Started to warm strike water to 163F. Put probe in to watch temp. Probe secured to side of pot with 3 clips to keep it off the side.*

While warming, I measured out the grain:

2 lb 4 oz Maris Otter

4 oz 20L Crystal Malt

Made the mistake of putting the paper bag full of crystal malt on the counter, which was wet with sanitizer. Poured all of my crystal malt into a plastic bag (I had more than what I needed for this recipe, and by pouring it into another bag, I could isolate the damp grain on top of the amount in the new bag), and used some of the slightly damp grain (it wasn’t very damp at all.)

10:18am: Strike water reached 163F. This was on probe thermometer. Thermapen measured lower, so waited until it reached the correct temp with Thermapen measurement.

Question 4: Does anyone else find a big difference between the Thermapen and the probe-type digital thermometers? The probe thermometer I have is from the same company that makes the Termapen, so I’m guessing it’s pretty high-quality.

Put grain in bag, and bag into pot. Secured with clips. Stirred. Temp 160.5F (too high?)

Turned off flame, since I thought it was too high. Stirred for about 10 minutes to try to get temp down. After 10 minutes, got to 158F. (using Thermapen for all these measurements)

Added 1/2C room temp water from sparge water to try to bring down temp. Got down a little bit (156F) [Note: Probably not enough water. What else could I have done?]

[color=#BF0000]Question 5: Is 160.5F too high for the mash? Temperature didn’t drop as much as it should have (most sources say it should drop about 10F after grain addition).

Question 6: If it is too high, what should I do to adjust the temperature? Is adding room temperature water the best thing to do here?

Question 7: How much stirring can I do here? Is it possible to over-stir, and somehow release tannins or oxidize the grain?

Question 8: John Palmer’s “How To Brew” suggests putting the pot in a warm oven to maintain temperature. This pot fits in my oven. Should I do this? Has anyone done this?[/color]

Covered with lid (on top of clips, so not completely covered, and with probe in) at 46 minutes. Thermapen reads 153, probe 162

41 minutes remaining. Temp fell below 150F in spots. Turned on heat on low for 1 minute. Temp around 153F at end. Recovered.

31 minutes remaining, dropped to 143F. Turned on heat for 5 minutes to get back to 153F. Recovered.

Realized that I didn’t need to sanitize the aluminum stockpot lid. Since I’m doing the boil in the Le Creuset, I need to sanitize that lid instead. I’ll do that while doing the sparge.

21 minutes remaining. Still at 153F.

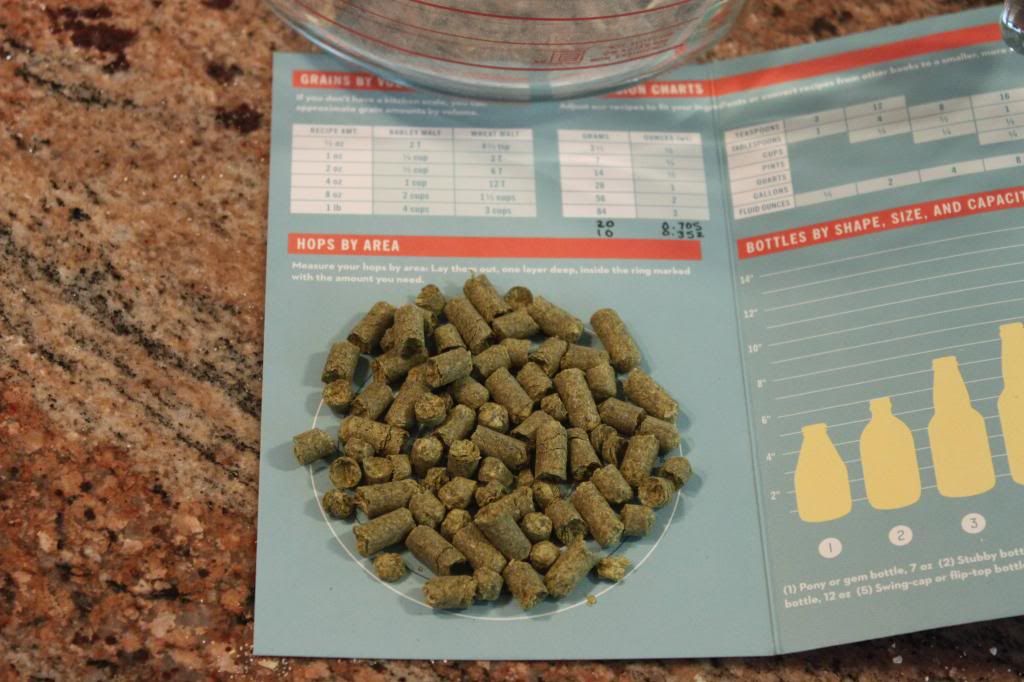

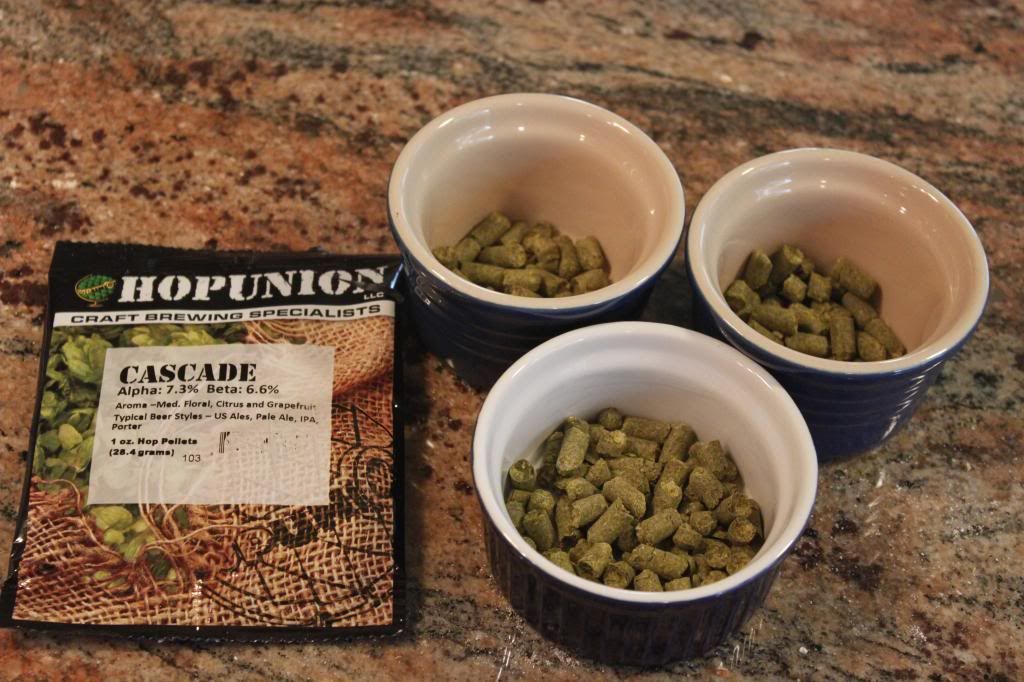

Measured out hops using “Hops By Area” in beer craft, since I don’t have a gram scale yet.

20g Cascade at 60 minutes

10g Cascade at 20 minutes

10g Cascade at 1 minutes

13 minutes. Still at 153F

7 minutes remaining, temp at 151F. Turned on heat for a minute. Back at 153F. Recovered

0 minutes. At 152.6F. Here’s a look focused on the wort, and another focused on grain bag.

Question 9: Should I use a finer-mesh grain bag?

Tied bag to microwave handle and hung over top of mash tun for 5 minutes.

Measured wort quantity. It was 15 cm below rim. This is a little more than a gallon of water. Need to get to 2 gallons, so brought 1 gallon sparge water up to 163 in the aluminum stock pot. [Had to add 2 qt room-temp Crystal Geyser bottled water to what I had since I didn’t have enough from what I left out overnight.]

Added grain bag to sparge water. Sloshed around (water didn’t fully cover bag), and let sit for 15 minutes. Temp after adding: 157. At first, I thought it was 5 minutes. Left uncovered for 4 minutes, then covered with a lid for the rest of the time.

Wort smells delicious! Tasted it (prior to adding second runnings.) Pretty sweet.

At end of rest in sparge, final temp was 149F.

Hung grain bag over lauter tun for a few minutes to drain.

Question 10: I know there are lots of ways to sparge. Would it have been better to slowly pour the water over the grain in this pot? I could have easily done this, but just followed the directions in the book. If pour-over, how many times should I repeat?

11:52am – Added all of second runnings to mash tun (now boil pot), and turned up heat to high to get to a boil.

Question 11: I did not take a SG reading at this point. Should I have done this? (Target was 1.035) If so, water was still hot. Is it ok to take a refractometer reading or hydrometer reading with hot wort? And, what should I have looked for? What corrections could I have made at this point?

Tried some of the second runnings. More mellow, but still sweet. Reminded me of the mugi tea I had in Japan (which I though was made of corn, but after looking it up online, I found it’s made of barley, so it figures it would taste like this.)

12:06pm (14 minutes in) – still not boiling. Stuck Thermapen in (sanitized). Temp 192F

~12:12 (20 minutes in)-- reached boil. Saw hot break. Here’s a video:

Added hops at 12:14, started timer (and almost boiled over, so I turned off burner…)

Question 12: what can be done to prevent boilover? I wanted to stir it, but didn’t. Wasn’t sure that was correct. Left a bunch of sludge on the upper sides of the pot. Should I stir this back into the wort?

Question 13: How much stirring should be done during the boil, if any?

@ 12:28 (14 minutes of boil)

@ 12:46 (32 minutes of boil)

@ 1:00 (46 minutes of boil)

@ 1:14 – end of 60 minute boil. Stirred with a sanitized plastic spoon in a clockwise direction for 30 seconds. Didn’t measure quantity at this point, but should have [Next time!]

1:15pm – put in sink with 10lb ice, plus whatever I had in fridge.

1:24 – added 14 lb ice, since most of the ice in the sink melted. Wort temp 118F. Now i can see why a wort chiller would be nice.

OG: 1.042 (measured with hot wort. Didn’t take a pre boil gravity. do this next time.) Target was 1.055, Is this bad? If so, what could I have done to fix it?

[color=#BF0000]Question 14: OG was 1.042, but the book recipe lists target of 1.055. Is this bad? What could I have done to fix it?

Question 15: Since I didn’t take the pre-boil gravity, what should i have done to try to reach that gravity? When should I have measured, and what should i have done? More mash time? [/color]

At 30 minutes (1:45pm), temp just below 70F.

Poured in 1 gallon fermenter through a fine mesh sieve and big funnel. Had more than 1 gal. (The fermenter didn’t have a 1-gallon mark. Fix this.).

Sanitized hands. Covered end of fermenter with right hand and shook for 30 seconds.

Took OG reading again with refractometer: 1.041

Shook yeast…opened. It foamed over a bit (open slowly next time.) Added to fermenter. Used 3/4, though i was supposed to use half. (it’s hard to tell how much I’m pouring out of the tube.) After adding the yeast, I sanitized my hands again, covered the opening in the fermenter with one sanitized hand, and shook vigorously for 1 minute.

[color=#BF0000]Question 16: I used more than half of the tube (which was called for in the recipe, more like ¾ of the tube. Will this be a problem? Use by date is 11/22, which means it was produced 7/22. Some viability has been lost in this time, so maybe not a big problem?

Question 17: Is there a better way to measure out “half” of the tube? Maybe shake, pour into a sanitized beaker first, then pour half back into the tube, and pitch what’s left in the beaker? If I do it this way, will the yeast be harmed by the sanitizer, going back into the tube?

Question 18: Can I re-use the ½ tube of yeast that I poured back into the tube? Is there a way to grow it into a full tube again?

Question 19: Should I shake the fermenter to aerate before adding the yeast, or after, or both? How long? (I only did for 30 seconds prior to adding yeast, and 1 minute after. I’ve seen elsewhere to do it for 5 minutes, after adding yeast. I’m guessing more is better here.)

Question 20: Should I just sanitize a piece of foil or plastic wrap and place over fermenter opening prior to shaking, rather than sanitize my hand? [/color]

Topped fermenter with rubber stopper (push all the way in, otherwise it will pop out), then inserted lower part of 3-part airlock, connected a tube to it, and put the other end in a growler nearly filled with sanitizer.

Question 21: I used the airlock + a smaller tube for the blowoff tube because I couldn’t find a 1-3/4” tube to fit directly in the mouth of the 1 gallon jug. I’m concerned that the tip of the airlock will get krausened-up and be ineffective. Is this method ok?

Tasted what remained in the pot (without getting any of the trub.) Bitter and sweet. Quite bitter, actually, but also quite sweet.

Question 22: Any suggestions on what I should do with the leftovers. Seems a shame to pour down the drain.

At 4:51pm (several hours after putting in the fermenter), I put on the temp strip. It’s at 72F.

Also put a plastic garbage bag around the fermenter bottom to catch any spills.

12:00pm the next day: Still at 72F, and bubbling away in the blowoff tube.