First time brewer here, with a question about fermentation.

Basically, how much fermentation is too much, and how would you rate my ‘first 24 hour’ progress listed below? (should I be concerned or is all well and good)

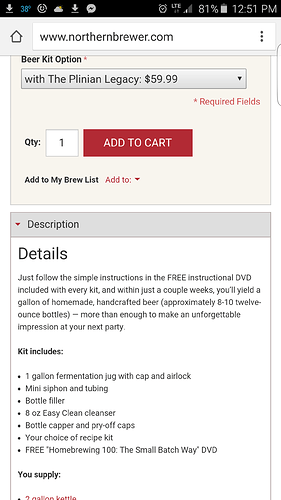

My brew day was yesterday (2/22/16) using the NB 1 gallon starter kit (Red Ale). Everything went well, and I followed the mixing instructions to the letter.

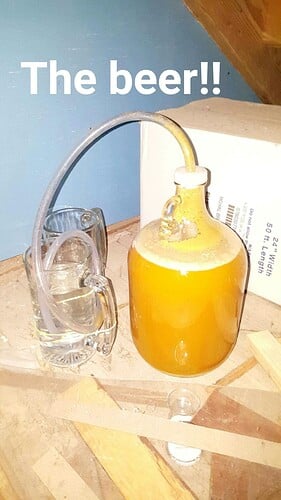

Here’s a picture of the jug after attaching airlock:

I left the jug to ferment on the floor in the corner of a dark room. Temperature is typically a constant 70 degrees, but can spike to 73 before air conditioner kicks in.

[Note: prior to brew day, I logged the temperatures in several places in the house and the corner location was the most consistent in temperature. The NB starter kit white paper says that my “Irish Red will ferment happiest at a temperature of 65-75F.” so this spot seemed the best. ]

After 8-10 hours, there was active fermentation(!) and lots of signs of spitting from the airlock literally dripping down the wall

I fought off my initial desire to pull off the airlock and clean it…

As of this message, it’s been 24 hours and the spitting on the wall has stopped and there is still occasional bubbling in the airlock:

Questions and thoughts:

- I wasn’t expecting much fermentation that soon, and wasn’t expecting to have to clean off the walls. Lol.

Was this due to the ambient temperature being too high? In reading posts here, a temperature in the low 60s is ‘better’ that the low 70s. Though, being a new brewer, it’s not clear ‘better’ means and what the change in temp will translate into from a taste perspective.

- At this point, is there anything I should do? (clean airlock?) or just wait two weeks and bottle everything up?

This has been fun so far, but I’m wanting to make sure that I’m learning as I go.

Many thanks!