Well, here I am, behind the eight ball again… We had a freeze last W/E so apples need to be processed… I made the grinder with a garbage disposal unit… thats easy… Now for the press… My wheels are spinning… I think perhaps a trailer jack would work? Anybody try this yet? It could be easy enough to make the upper yoke adjustable so you could take it right out of the way as I load the barrel… ?

Input needed here… I have to make juice this comingW/E…  Sneezles61

Sneezles61

No need to rush - you’ll get a better juice yield if the apples sit in buckets for a couple weeks or so before you press them. When the surface looks a little shrively, that’s a good sign.

I’ve seen people use a screw jack with a round wooden foot to squish the apples in a bucket. I suppose you could rig up a lever with a plunger going into the barrel, and then just suspend weights from the end of the lever. Kind of like an old school bottle capper.

The “foot” on my press is a round piece made of 2” thick maple boards laminated together, with a cross-piece that goes the opposite direction of the other boards, and the screw jack presses on the cross piece. Not sure if that makes sense? I’d take a picture but it’s raining.

Similar to mine .I drilled a bunch of 1/2" holes in a plastic bucket put the smashed apples in a paint strainer bag and press with a scissor jack. I have it set on a cookie sheet with a a hole drilled in one end to catch the juice. Works great

Well, I didn’t drill a mess of holes in my “barrel” I still think of a trailer jack… its the one that holds it up… lets it down onto the ball… My press disk is a 1" thick of plastic from a counter top… hhhmmm… I’ll do what I can to can to plaster pictures on here…

Hey Pork Chop that rain was here for a few days too… I just wish it would cool right down and snow now!  Sneezles61

Sneezles61

Funny you mention the trailer jack. I just got a new utility trailer and took off the cheesy jack stands and replace d it with a swing stye. As I looked at the one I took off that’s exactly what I thought it would make a nice press

I made my pan for the press… I have all the stuff I need now to construct the press… I’m heading out with a growler of home brew to plot and scheme tonight… Tomorrow will be the build up day… I have like a dozen paper sacks full of apples in the garage…A friend who will bring a 55 gallon barrel full of them over too!

So if all goes well, I’ll make juice Sunday… So 1 campden tablet per gallon? This stuff may have to sit for a few days before it get some yeast added… I can get 5-er going with the Kviek… Need to test many more yeasts just because I can! Sneezles61

I bought a top screw A frame jack… I’ll make the yoke so it can come apart… should I have to replace the jack… Did I mention 19.5" of travel length?

Pics of the build, please! What other yeasts do you have lined up? Correct on the rate of campden tabs. Should be fine under an airlock for a few days.

How about a gallon of cider left alone, no campden, and letting the wild yeasts ferment?

I will take picts… I haven’t really put a bunch of thought on the other yeasts… Tomorrow I should order some… Along with Kviek, I do have Whites 001, I think Whites ESB… 1969?, And in the fermenter Imperial Gnome… Give me some more Ideas…

Yeah, I will leave one to ferment naturally… I have a plum tree… I should see if theres a plum or 2… Sneezles61

I’ve been wanting to try belle saison in a cider. I don’t think it’ll throw esters, but it produces glycerol which should give it a more full mouthfeel. I’d also go with the ESB yeast for sure.

Alrighty, some Belle saison… On its way… The ESB was Wyeast 1968… WHEW, I tend to forget… Ever try make cider with a lager yeast? Sneezles61

Haven’t tried it… but I like the idea! I might be concerned about sulfur. Racking through a bit of copper pipe might take care of that, though.

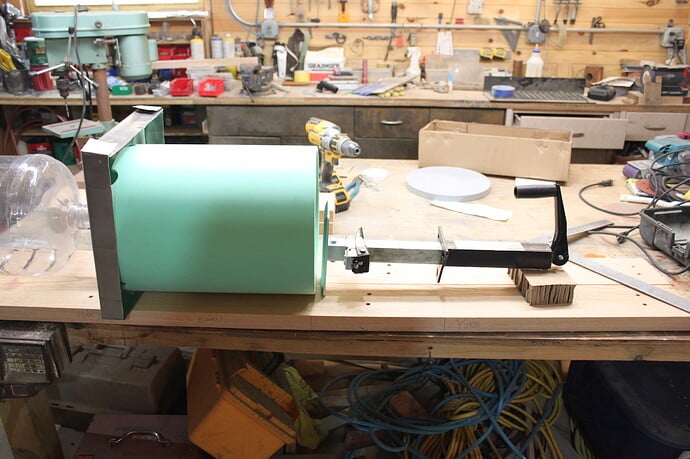

So this is just about done… The top with the jack on it comes off via the 2 pins on each side… That foot you see is adjustable! Tomorrow I’ll rivet the corners of the pan together, and its ready! I have to wire up a switch to the grinder… and get a hunk of hose to put on the output end… Then time to make some juice! Sneezles61

Looks awesome! Something to consider with the grinder, mine is attached to the press itself and grinds right into the bucket. Pain in the arse. It would be much better to have it mounted to a separate stand with a different bucket, so that one bucket could be pressed while the other filled. It would make the process go much more smoothly to have two buckets in work at once.

Mine are separated gizmos… I’ll get some pictures of the set up in operation… Sneezles61

I love your design! Holes on the side of the barrel are important because some of the juice will want to go up when pressing and bypass your pressing disk. If you have holes of the side, you won’t have that problem. That’s the problem I have with my system which I plan to modify at some point. I plan to go bigger with the press at some point which is my bottle neck. My chopper / bucket blender can chop apples a lot faster than I can press.

Yeah, thats what heard… The pressing is slow… I’ll add some more holes up the barrel… Thank you! Sneezles61

The holes need to be on the side. I don’t even have any on the bottom the clog immediately. I load paint strainer bags with mashed apples and through one on top of other. The juice comes out the top and sides. Don’t make the foot to big. About 1/2 inch clearance all around

I have a square wooden lattice that the bucket sits on in my pan, that consists of three strips of wood running one way, and a bunch of strips going the other way with about 1/4” spacing between them. This lets the juice run out the bottom and sides. Good call on the paint strainer bags, I have heavy mesh bags that fit the inside of the bucket, but paint strainer bags would probably work about as well.