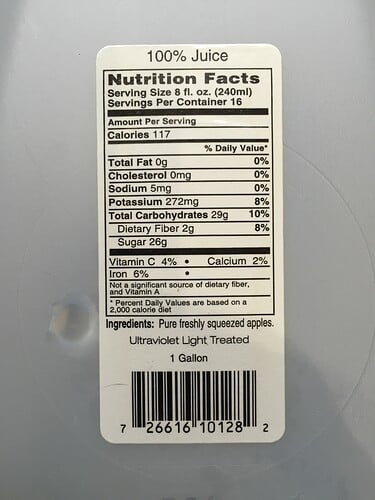

I use a local cider I pick up from the local heath food coop. When I find some time I need to explore the local farmers markets here in the bay area to see if I can get a better deal. This is not the cheapest cider (I want to say its $6+ per gallon) but it is quality cold pressed UV pasteurized fresh local cider.

It took FOREVER to clarify. I racked it at least once from the 6.5 gallon to the 5 gallon once a lot of the sediment had settled on the bottom. Maybe a second time as well. It took at least 8 months to clarify. I didnt think it was going to ever happen, had to eventually just forget about it, then it seems to have worked its own magic when I wasnt checking it every week.

I also add some Brown Sugar (two pounds) and some Black Tea. Here is my whole basic recipe (at least for this year):

5 Gallons local grown/pressed apple juice - UV pasturized

2 Lbs Brown sugar

1 REALLY strong cup of english breakfast tea

1.5 tsp Pectic Enzyme

1.5 tsp Acid Mix

1 tsp white labs yeast nutrient

1 packet White Labe English Cider Yeast

This latest batch I did no boil (previous one I did)

I instead took about a half a gallon and boiled that to dissolve the sugar in, then rapidly cooled the sugar solution under 100 degrees.

poured the remaining juice into a 6.5 gallon carboy

added the cooled sugar solution to the rest of the juice

then put in all the dry ingredients (pectic, acid mix, yeast nutrient) and have it a good shake before aerating it for an hour (little aquarium pump with a 500 micron stone).

Original gravity for both batches was right in the 1.07 range. Final gravity for the one I just bottled was a hair under 1.0 (0.999)

I then poured off about 500ml into a sanitized beaker and pitched the yeast into that, to create a starter. I let that go on top of my fridge for 12 hours.

The starter was so the yeast could multiply and acclimate to the mixture, while the pectic did its job on the larger batch.

After 12 hours there was no action on the carboy’s airlock (which is a good thing, no natural yeast was doing its things in there) and quite a bit of yeast build up on the starter, so I pitched it in.

Within 24 hours it has a 4" head on it and a lot of action on the airlock.