Hello how accurate is tapering the probe to the side of your fermenter vs using a Thermowell??

I used gauze and duct tape to make what looks like a giant gray band-aide. The probe gets inserted under the pad, the pad is thick to insulate the probe form the surrounding air. It works pretty well.

But to the direct question. How does accuracy compare? Well, I imagine it’s like using one of those forehead thermometers versus jamming a thermometer up your butt. Probably less accurate, but good enough that neither me nor the doctor want the ‘better’ data.

Nor the taste of one “butt thermometer”…

Sneezles61

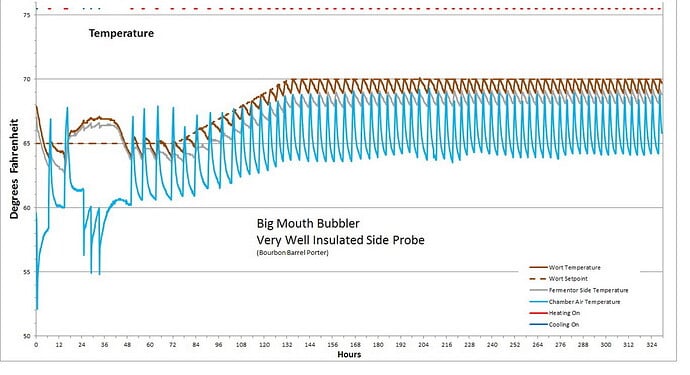

Here is temp in the middle of the wort, on the side of a big mouth bubbler, and, the surrounding air. The probe on the side was covered with foam insulation strapped tightly to the side and with expanding foam injected, so it was very well insulated.

The chamber is an old refrigerator. Temp controller is a home made proportional controller.

Max difference between wort and side probe is less than 2 degrees F.

Note that temps are not changing rapidly here. In the case of a very rapid fermentation where wort temps are climbing quickly, the outer probe will lag the wort.

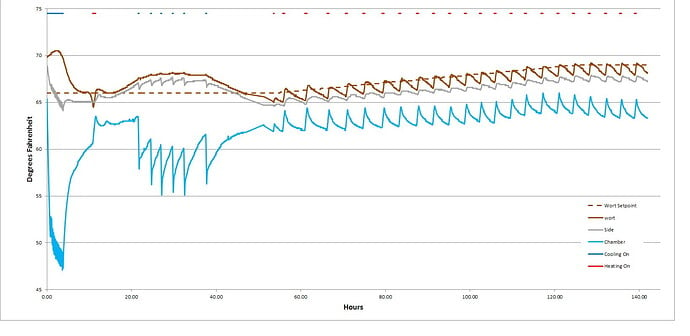

Here’s one where, early on, the wort ran a few degrees above setpoint and the controller drove the refrig pretty cold to control it. With the significant temp difference between the wort and air temps, the side probe was as much as 6 degrees F from the wort temp. This was a glass carboy. Side probe was covered with foam insulation and held tight but no expanding foam injected.

More important than the temp difference may be how well the probe keeps up with change. If the side probe had been controlling here, it would have turned the cooling off at about 1 and a half hours, when it fell below setpoint, but the wort was above setpoint until about 10 hours.

Fascinating Steve!

Sneeezles61

Love the hard data @Steve !!!

I still say, bottom line, the external monitor is “close enough for government purposes”

But it should also be possible to characterize the system and compensate for the difference in software.

The external probe seems to have a fixed, proportional distance between the internal and chamber temps. I’d expect to find that that proportion is a close match to the ratio of the insulating value of the carboy wall to the insulating value of that foam.

I mean you could get into higher order perturbations too, cause you really have a couple layers of insulation because the thermowell also insulates its probe, albeit in a tiny way. And there’s also time lag… and calibration of the probes…

TL/DR this fascinates me as an engineer. But I don’t think it makes a practical concern as a beer brewer.

True story: I know someone who worked at a major pharmaceutical, who worked with ‘biological’ products. I said, ‘I can control my fermenter to within ±0.5°C, how does that compare to industry?” The response was “our standard is ±2°C.” I’ve since loosened my settings to safe the life of my chest freezer compressor.

@jmck I agree the external probe works fine as long as there’s some sort of insulation, like your giant band aid, and the difference between air temp and wort temp is not very large.

A year or two ago, I came across some posts, here and elsewhere, claiming that the internal vs external temp difference was small. It sounded reasonable but none of those claims had anything to back them up, so I added a probe to my setup to find out for sure. When I saw the original question above, I remembered my experiment so figured I’d share.

I was inspired by your post long ago and originally got into this when I realized that fermenting in a refrigerator with a typical temp controller leads to over cooling the wort, especially for ale yeast. The typical controller turns the refrigerator off when the wort is down to desired temp, say 65, but at that point, the frig may be down to 40 so the wort continues to cool until the frig warms up.