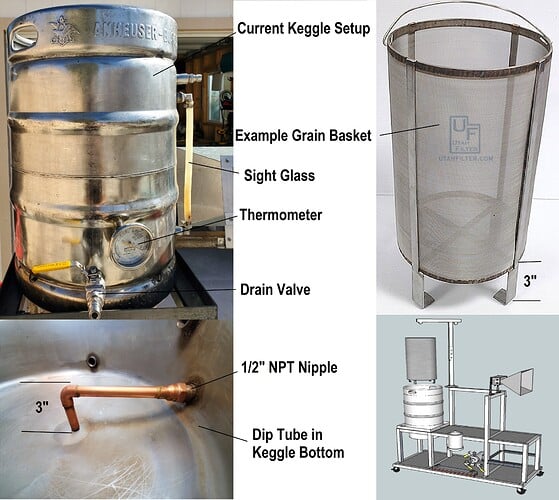

I have questions and hope to learn from anyone with direct experience with brewing in a basket in a keggle, which I am trying to transition to. I’ve historically done extract and mostly now all grain brewing using an igloo cooler for a mash tun, and a Budweiser keggle as my brewpot. I am ready to move on to BIAB (grain basket in a Keggle). I have several questions for anyone who has done this. BTW - I know about using a bag, and that there are kettle/basket combos out there but I am dead-set on using my beer keggle and a grain basket. Anything you can share with me about that would be of interest to me. I attached a picture of my rig, which I am fabricating now.

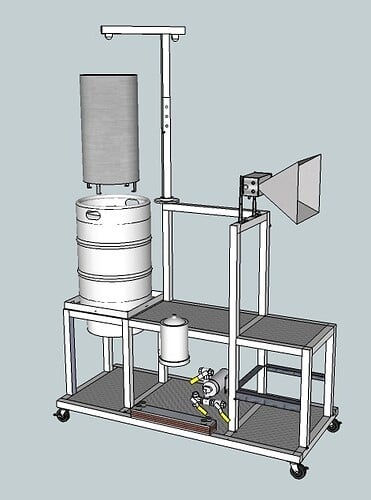

What size basket did you use for your keggle, width and height and hole size in microns? I believe it is important for the basket to be as large as possible relative to the keggle volume. Or is that really critical? I want to be able to do 5 gallon brews and a 10 gallon brew occasionally. What height should the basket be? Where did you get your basket, I know about Utah Diesel as one source? At this point my keggle has a 12 inch hole cut into the top of it, and I’m thinking of either making that larger or cutting off the entire top of the keg. I am going to modify my current dip tube so that the feet on the basket are as short as necessary (right now the dip tube would require the basket to be 3" off the keggle bottom). How can I lower the 3" clearance to my dip tube? I would like to drop that to at least 1.5" from the keggle bottom. My temperature probe is currently 2.5 inch stem so that has to be removed also (or changed), and I might replace that with a stubby if I can find one with a short enough stem. What did you do to measure temperature in the keggle before putting the grain baske

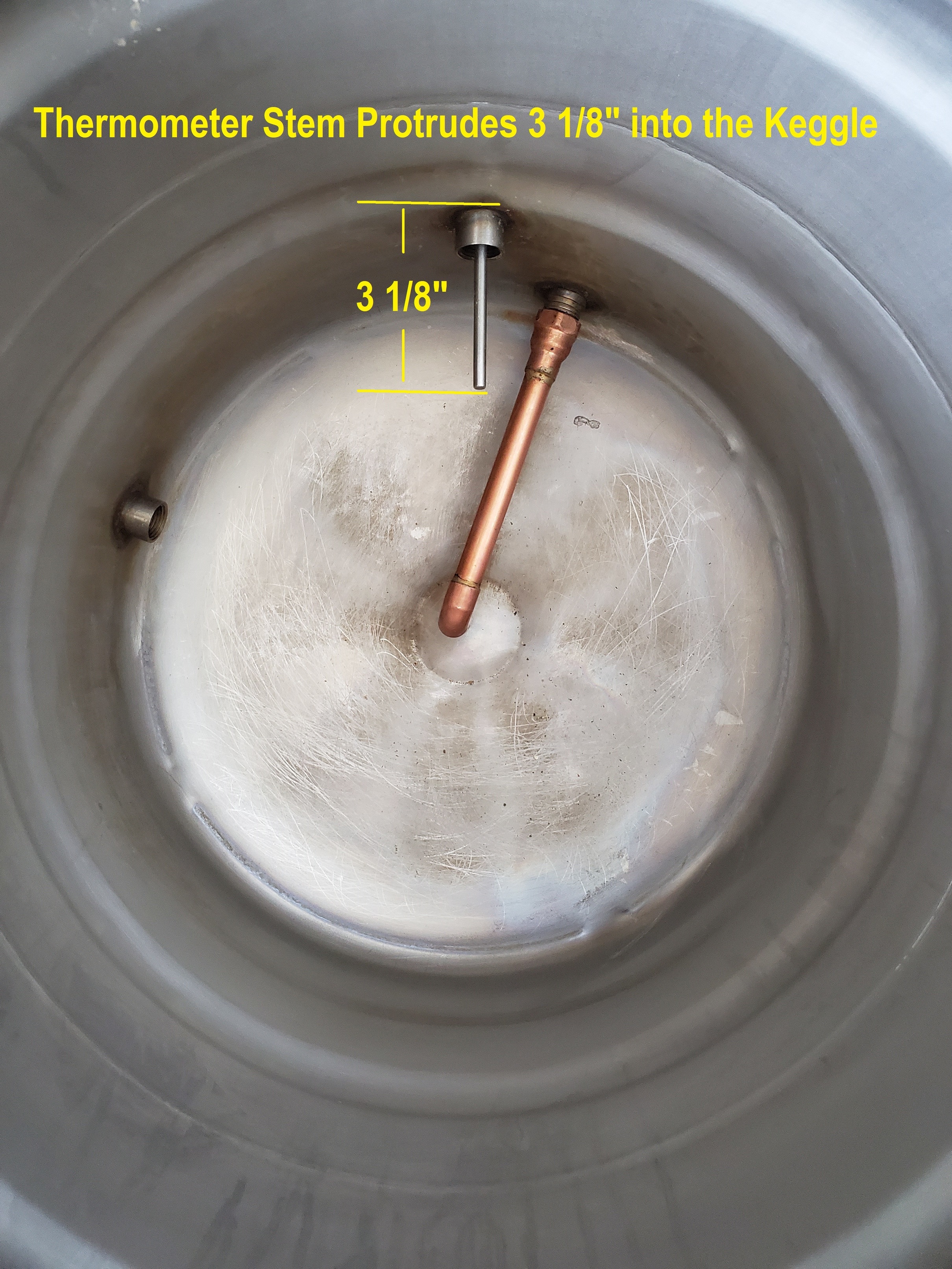

How far in does the thermometer probe go? Hard to tell from the photo. Will it be in the way of the basket?

Looks cool BTW

My thermometer has a 3.5" stem, which protrudes into the keggle 3 1/8" installed. I am either going to find a shorter stem thermometer (that will correctly read temperature), or maybe eliminate the thermometer. It is currently, obviously in the way. Always has been actually, but I have read that a thermometer with a stem that does not protrude from the pipe coupler won’t accurately read wort temperature.

Ditch the thermometer. I’ve never understood why they are in the BK as they are only in the way. Get a thermapen. Just saw the classic on sake for $59 and it’s an instant read.

As for the tube, work a 90° right out of the kettle coupler. Then you’ll be able to draw wort off the side of the kettle and once you’ve chilled perform a whirlpool to keep most hop debris out of the fermenter.

Thanks loopie_beer, your suggestion got me thinking. I did an ExBEERiment, side by side temperature readings of 6 thermometers I own (kitchen, garage, brewgear) to see which is most accurate. Turns out the one I was using in my Keggle is not very accurate. I have two of them and neither measure accurately. Perhaps they are damaged due to overheating (I have probably exceeded the case temp max 150F since they were installed on my Keggle) but even after re-calibrating them, neither measure accurately at temps other than the calibration temp. SO…I am NOT going to use an integrated thermometer in my Keggle. I am going to use one I bought a couple years back. Very accurate and instant read. I can hang the wire/probe in the Keggle or mash and get good readings. This solves my original problem of the thermometer being an obstruction in the Keggle. I asked the forum editors if I can publish my results on this forum (casts a negative light on some brand name thermometers). If I get the go ahead I will do that.

Hello, I am of course the originator of this thread and I would like to refocus it. My original posting was admittedly overwhelming, so I’ll narrow this down to specifically what I am looking for. If anyone has actually done this I would love to hear your feedback and advice.

What size grain basket are you using in your converted Keg (keggle), height and diameter? My keggle is a converted standard 15.5 gallon beer keg, and the interior diameter is approximately 15.25 inches. Thanks much in advance, and cheers. MikeBeer

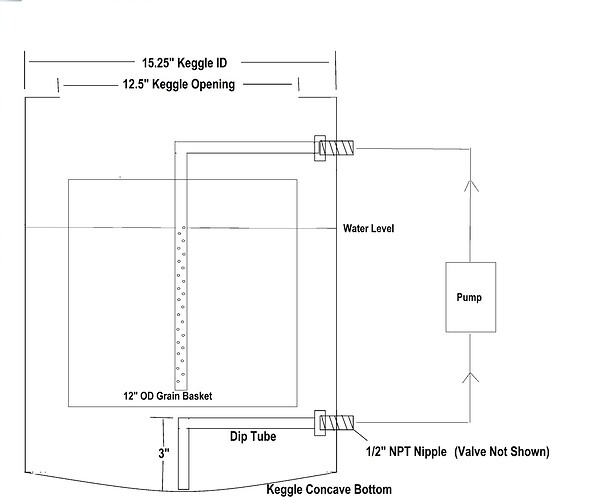

Having a great conversation with myself here so far, so what the heck I’ll continue. Turns out that I probably won’t be able to fit a grain basket more than 12.5 inches in diameter into my 15.5 inch OD Keggle, and I’ll also have a couple of inches space below the basket for the dip tube. So to summarize, I will have quite a lot of “Dead Space” around and under my grain basket, which I assume will result in lower efficiency. If I use a chugger pump to recirculate the wort during the mash, with a vertical copper pipe with holes mounted vertically in the grain basket, will this compensate for the dead space? That would “push” the wort from the basket interior out to the dead space, and down out of the basket, which the dip tube would then pick up back to the pump for continued recirculation. Any opinions on this approach?

I’d be more inclined to use something that “showers” the top of the grain basket so that you have even rinsing from the top down. I’d be worried that a vertical pipe would just channel, and reduce efficiency.

Is your 12.5" diameter restriction because of the opening in the top of the keg, or do you plan on chopping more off?

On that note: it would appear Brew Boss has something called “COFI” which is similar to what you’ve described. Maybe it does work? I dunno, I’m still stuck in my ways on a 3-vessel system.

The vertical return tube that feeds the grain bed would have holes along the entire length of it, aimed in all directions(angles), extending from the top of the grain bed to the bottom, so it should feed the grain bed uniformly I think. Yes the top rim/handle of the keg is ~13" ID, and I don’t want to cut it off, just looks better as is, so that is ultimately the limiting factor on what will fit inside the Keggle. I have not committed to this approach just yet, I’m still sorting it out before I expend any labor or funds on it. Appreciate your comments and ideas.

I think most 1 vessel systems use a vertical tube. I too believe in my 3 vessel system so not much help here.

No help from me. As well happy with my setup as it is right now.

I cut the top of one of my old keggles following the seam at the top… I did leave the handles in place…

My basket is from Utah Biodiesel… about the size of a 5 gallon bucket.

The out put port, I used a Tee… Thread it on so the port in the middle faces down. You now can thread thread you thermometer into the end that is straight in line with the port of the keggle…

No way to avoid the amount space under the basket… which I never found to be an issue.

I use a pump. Get some threaded hose nipples, 1/2" variety and 1/2" silicone tubing. You’ll connect from the output Tee to the pump… and then leave a long piece of tubing from the output of the pump so you can direct your wort over the top of the grain bed…

I’ll assume you are using propane? You’ll need a heat shield of sorts to protect the output side of you keggles from the intense heat… Sneezles61

Thanks for the feedback. I have been thinking after reading all the replies. The pics here show my decided approach, for now, and I’ll only change after a few brews if I am not getting good results. I am fabricating this now, a rearrangement of a previous 3 vessel system I’ve shown on this forum before. I’m staying with my keggle with a 12.5" hole cut in the top so I can still use my pot lid that fits it well. For a basket I’ll use an existing 12" OD SS Cajun Cooker strainer basket, with a grain bag inside it. I found some stainless steel pipe clamps to use as feet to keep the basket weight off the dip tube. I will be doing continuous sparging during the mash. The return to the Keggle will be via a vertical copper pipe with holes in it, through the center of the mash. I’ll play around with this setup and if all this does not meet with my expectations I’ll buy a Utah Diesel grain basket.

I can’t get my stuff to post pictures or I could show you old/previous set up… My new one is a one kettle system too…

I have to ask… Why do you need a lid? Sneezles61

Hi Sneezles61. I would only use the lid during the mash to hold temperature, and an insulating cover if I need it wrapped around the Keggle. Eventually I plan to use my hop rocket to control temperature automatically…once I get the rest of this working. Still need to lay out and try the plumbing arrangement.

Tell us more about the horizontal grain mill.

Hi Voltron. I should have anticipated a question about that. The grain mill is mounted on hinges so I can swing it down over the grain basket vertically to mill, then swing it out of the way, stowed until the next brew day. In this image I left it “horizontal”…it should be shown rotated further clockwise into a stowed position. I got tired of setting up the milling operation every time so I added it to my rolling brew factory. I know grain contains lactobacillus, etc., and some say it should not be milled near the fermentation vessel or bottles but I am very careful about that. Has not bit me so far.

Looking forward to seeing the finished results!