[quote=“doc280, post:98, topic:25998”]

At week four, the beer is dead.

[/quote]This has to be oxidation then. I’ve never experienced it like this. If it were an infection then you probably would have explosive carbonation by this point. I suppose it still is possible that you don’t like the hops in the beer. Do you like hops in things like NEIPA?

Carbonation is consistent to every bottle and the same is true with all the previous batches.

I can not say I have ever tried a NEIPA, but have sampled many different IPAs brewed here in the Carolinas and the west cost and never experienced the favor I get from my brews.

I am hoping that the bottles were properly cleaned prior to sanitizing…(sorry for asking).

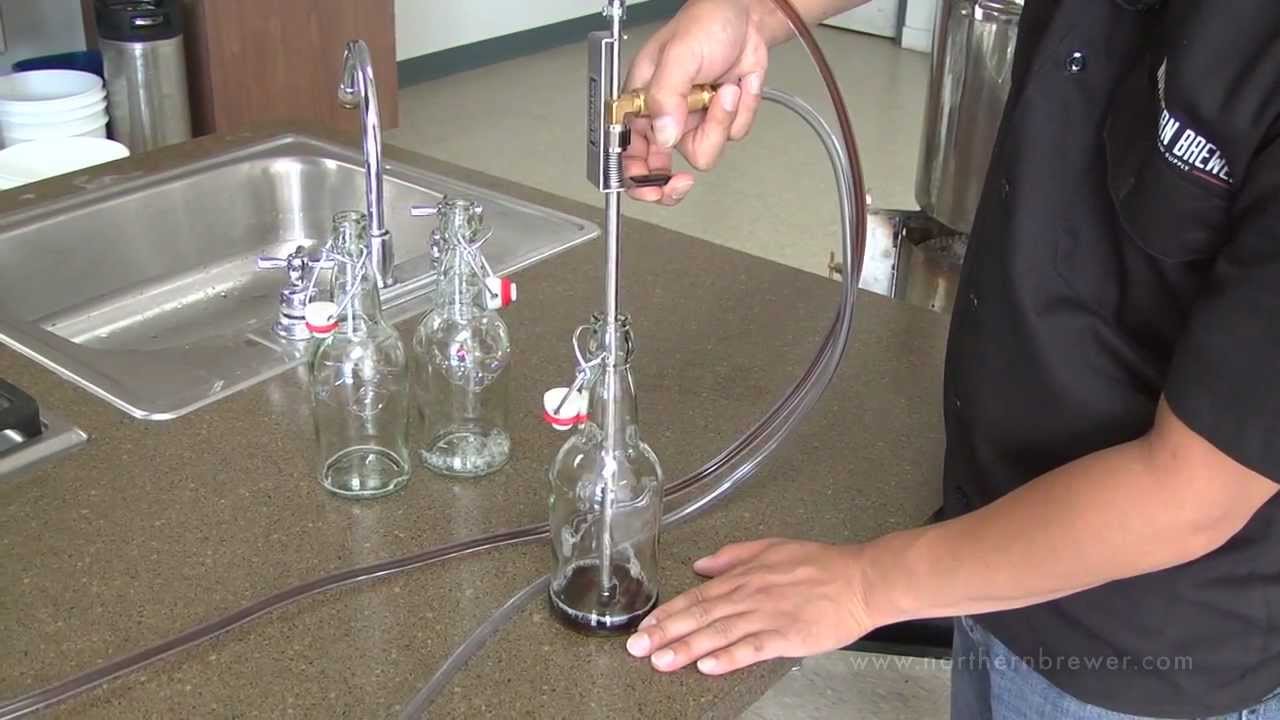

Here is what I use for Carbonation (works perfect everytime).

This cost some money for Keg Setup and Beer Gun but well worth it.

This is nice for the CO2 Tank.

One for the keg, one for the beer gun.

I have 2 CO2 tanks (beer frig and Spare for bottling or backup to frig).

I am hoping it was the oxygen cleaner that was used. The reason a said Neipa is that they tend to be hazy and unfiltered with a lot of hop flavor. Hops can be grassy and the bitter from them can be metallic. But you did not use very much hops in that Rye

I bottled for 2 years with SA-04 and SA-05.

I got a lot of farm house tasting beer on occasion.

My beer only stated getting better when I

1.) I stated using WLP001 CA Ale Yeast (with or with yeast starters)

2.) I started kegging (bottling with beer gun)

Sorry if that offends anyone (not my intent),

Lots of people bottle with priming sugar but to me those beers they always taste funky.

The beer always taste different between point of bottling then after 2nd fermentation in the bottle

and then you could never really control the Carbonation as this is so dependent on yeast vitality.

Home brewers do not have a controlled process here…

The bottles are always cleaned right after use, then cleaned and sanitized right before bottling.

I was hoping for the One Step as being the problem, however the the Private Rye bottles were rinsed with distilled water, so leaning against it now. My hope now is for the bottling wand to come though for me. Just maybe filling the bottles with the spigot was introducing oxygen.

I disagree with the one step being completely rinsed… And I hope you didn’t rack from the primary to a secondary… then to a bottling buckets… I do like you have Star San… Doing a little re-reading, you’ve also mention you thought it was “dryer” after more time carbonating… I will agree with Tom W about picking up off flavors from bottle conditioned brews… Your racking tubes aren’t sucking in a bit of air? Sneezles61

What is the taste you are getting now.

[facepalm] I do not even no where to begin with that Tom.

I could live with the One Step being the issue, we will see.

I was doing primary spigot, tube, to secondary. Zero air in the tube and tube was in the bottom of the secondary. No bottling bucket, secondary straight to the bottles.

I have bottled the IPA and I will recap all the steps I have taken to try to have a good outcome.

@doc280 you will figure this out. If this batch does not fix your issues then we are going back to the beginning. The fact that you did not ever encounter this issue with your Mr. Beer kits will be our next round of inquiry.

Oh, I dunno… the CO2 bubbles from my bottle conditioned beers do seem a bit grainier than CO2 from forced carb…

Ok there is clearly a difference between having yeast in a bottle and not having yeast in a bottle. I will not argue that. Saying that its bottle conditioning itself that is the cause of docs issues is not helpful. First it’s patently processist (  yeah I just invent that word) and we all know that for the 5000+ years we have been brewing beer as a species we have only had forced carbonation for the last 150.

yeah I just invent that word) and we all know that for the 5000+ years we have been brewing beer as a species we have only had forced carbonation for the last 150.

Edit:added another 2000 years to the history of beer… shout out to Godin Tepe.

What, are you some kind of geneazymurgist? I’m just messin’ with you bud!  Besides, not being a super taster I can’t taste the difference between CO2 producer by yeast from CO2 produced by combustion or various industrial processes. Heck, I can’t even taste the difference between mashing in a tun and BIAB!

Besides, not being a super taster I can’t taste the difference between CO2 producer by yeast from CO2 produced by combustion or various industrial processes. Heck, I can’t even taste the difference between mashing in a tun and BIAB!

[quote=“porkchop, post:114, topic:25998”]

I can’t even taste the difference between mashing in a tun and BIAB!

[/quote][Rolls up sleeves hackles raised]

A recap of the Kama Citra IPA, which was bottled today.

Kama Citra IPA extract kit 5 gallon.

Water used -distilled.

Sanitizer - Star San.

Gains steeped 150F for 20 minutes.

60 minute boil - the different hops added at directed times. Hop spider used.

Wort cooled in ice bath 25 minutes.

Wort placed in two LBKs and distilled water added to bring up to the 2 1/2 gallon mark.

Wort was 68F when US-05 yeast was pitched.

The LBKs placed in the fermentation chamber with temp set at 62F.

At 14 days dry hopped. Hops placed in a hop bag, weighed down with a one inch glass marble.

Day 21 bottled - 12 bottles primed with corn sugar (had some left over) - 12 bottles primed with cane sugar. Bottles filled directly from the LBK spigot using a bottling wand.

Bottles stored at 73F in the dark.

At bottling the sample taken had a blonde yellow color with a slight haze, nice citrus smell and very pleasant citrus hop flavor. I would call this a pale ale (maybe the hop spider and hop bags limited the hop favor transfer), but I love it, just hope the off favor does not get it.

Your process is sound. From here, the only things that could bite you would be a cold-side infection to a piece of equipment. If you really want to monitor things, use your hydrometer at each stage to make sure the specific gravity isn’t much lower than expected. Infections tend to ferment sugars that yeast cannot ferment, which can be detected in a hydrometer measurement being much lower than expected. Like under ~1.005 with US-05.

The only variables, to me, would be the LBKs and the plastic bottles. Other members have used them without issue, but not having used them myself, they’re still unknowns.

Just be advised, citra has a really short shelf life in finished beer. A few weeks, the aroma and flavor is great. Then it just dies. I’m sure that someone with more scientific background could explain which compounds in citra hops are so susceptible to oxidation. But just so you know, if the flavor suddenly drops off and you’re left with a harsh bitterness in your beer, it might not be your process. Just a hop that’s seriously impacted by oxygen exposure.

Thanks for the information. I am going to try one at two weeks and if the taste is good I plan on loading as many as I can in the refrigerator. I will leave a few bottles out to sample at three and four weeks.

You might as well try one at one week while you’re at it.

I can do that.