I am there with you. I don’t dislike the electric brewing system, I quite enjoy it. I just think I need to build more of it to actually make it work. The only other option id have would be to continuously stir the boiling wort with my mash paddle. I don’t want to walk away from anything but I do want to have my system do more work for me. Work smarter, not harder… Right?

Once I create a tubing/piping/pumping system, then I can make sure the wort is always moving and shouldn’t be able to burn on the heating element. How do you make sure your wort doesn’t burn with the electric element?

Here is my setup

3 tier setup, MT, HLT have automated valves. Pump connects from output of MT and then routes back to the top of MT. Heating element (on/off only), valves, and pumps all controlled by PLC, live RTD feedback for temperature.

I am going to build another “tier” and put another automated kettle with a port in the bottom for strike and sparge water…and pump to move to HLT or MT. To make my electric kettle work, I would need to alter my boil kettle to have a port on the bottom and piping/tubing to a pump to send back to the top to keep wort moving around, and I could also install a SCR to change the temp of the heating element.

The SCR is quite cheap… Even if you only use it for a year… 20 bucks is going to give you more things to think/ponder about…

Maybe you have to turn your element on for say 2 minutes… Then off for 2 minutes…

Also, I wonder if it was on brewershardware.com that showed how to add a port… If your handy and have some oxy/acetylene torches you can silver solder that yourself… A nipple is better than a coupler in my mind…

Sneezles61

I just use a carbide hole saw, then mount with couplers, o rings, and ss nuts. I then use high temp, food grade silicone caulk to seal it, works pretty well.

I know a lot of people use temp controllers with SSRs, but that’s still on/off so I am afraid it would still have issues. At least with an SCR I could control the voltage to my heating element which should decrease power. I already own a $20 one but I was hesitant to use it because that’s a lot of power running through a dinky thing. Also I can only get down to 120vac and up to 230vac, so I dunno if 120 is low enough to keep it safe. I guess I could get two SCRs, one for each hot leg, then just tweak both knobs back and forth, don’t know how thatd turn out. How do you do it, sneezles?

If I use a SCR, do you think I still need to circulate the wort around as well?

Mine had three places to land the wires… 2 line voltage and one common… So that’s how it’s wired… I’d have to go look, what 3-4 years of use… I check the heat sink and never had it so hot I couldn’t keep my hand on it…

I suppose you could pull the oven controller off the stove too…  …

…

I recirc continuously…

Sneezles61

If you ever get the chance, can you send me the scr you use? Mine is only one leg that is controlled, it’s for 230vac with one hot, so the best I can do is plug one hot of 120 into it with the other hot straight to the element. If I can find your controller, that’d be a huge help

Here’s the wiring diagram for mine

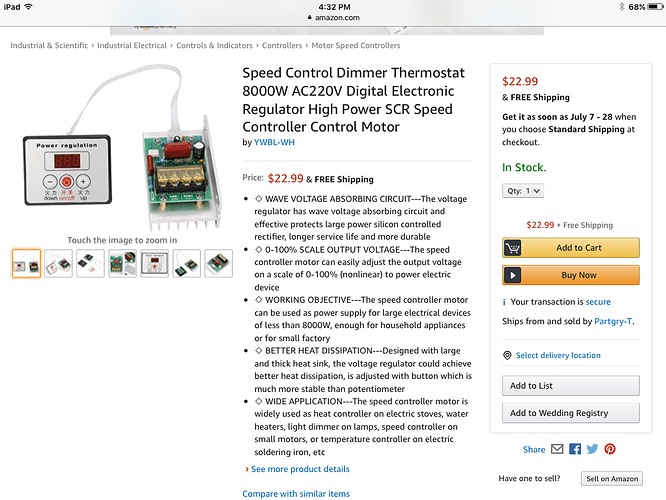

This is very similar… Mine is a RioRand… I see the price has gone up a bit. Amazon…

Sneezles61

1 Like

Thanks man, that’s great. Once I get a pump setup to recirculate the wort, I’ll give this a shot. Until then I will stick with propane

Although I encourage you to get an SCR so you can control the boil there is an easy fix…

You need to get the ULWD element. Here’s one for $40.00

1 Like

Do you think both are necessary? Meaning I know I need an SCR, but do I also NEED an ULWD? Not a huge deal, I would just have to do some work to remove the LWD, I can do it but I’d prefer to leave it alone if I could get away with it.

Also I need to find one that can handle roughly 7kW, since I have a 30 amp supply that I can’t swap out. I think that’s why I chose my LWD in the first place, it was rated higher. I know it’s just a resistor so it shouldn’t pull more amps than it needs (24 amps or so), but I just don’t want to accidentally burn it out in case of power surges. What do you think?

IMO it’s paramount to have a ULWD element as you’ll get lower heat per square inch.

Would I risk burning out the element if I ran a 30 amp service to it though?

Edit: nevermind, I was thinking backwards about electricity haha.

1 Like

@sneezles61 how do you circulate the sweet wort during boil? Agitator inside the pot, or pull from the bottom into a pump and back to the top of the pot?

With a ULWD element you shouldn’t need to recirculate during the boil. And if you recirc it will take FOREVER to get to a boil.

1 Like

@loopie_beer Would I still need an SCR if I swapped to ULWD?

In theory, I could only start circulating once the boil begins? I’d already have the pump, so it’d just be a matter of creating a port in the pot to drain out to the pump.

@sneezles61 do you use a ULWD heating element with your SCR and recirc setup? I’m not trying to copy you, but if you have a system that works, it’s a good place to look

I have 3 ports near the bottom of my kettle… One is a triclover for the element… The other 2 are out and in… I pull out using a dip tube… The other is my whirlpool port…

I don’t really have any problem getting to boiling… It’ll get there real quick while recirc… That’s usually when I have some problems. I’ve learned to not rush to a boil…

I wonder if there isn’t pictures in my electric kettle build…

Sneezles61

@sneezles61 ahhh see I always thought to pump back to the top, but angle the tubing around the curve of the pot so that it would create a whirpool of sorts. But you take out and put back, both at a low level?

Yes… But I do have a manifold that I can choose where to send the wort… I do have a long hose that I use mostly for mashing… Then I put it through the chiller…

Sneezles61

Nice, I just searched for your post about your electric system, I even posted on it a while ago.

Is your heating element a ultra low watt density, or just a low watt like the one I currently have. If loopie is correct and I don’t need to recirculate if I use a ULWD, then all I would need is an SCR. But if you have this type of element, and still recirc, I would look into that

Basically I just don’t want to do more work or buy more stuff than is necessary. I like building stuff, but I don’t enjoy wasting time on something that is detrimental or something that doesn’t even help. Don’t put lipstick on a pig, right?

Element is from brewhardware.com… I’m not sure how heat is dispersed in my element or any other for that matter that will or won’t heat something without burning… I’ve found that watching my power and remember the percentage has gotten me to my current adaption…

Sneezles61

PS… I was wondering ifn you’d forgot about that…

…

…